Mahan Industries. Owes its success as much to its superior quality and manufacturing processes as it does to a strategically defined business model handled by professional business leaders with vision, acumen and integrity, aided by a team of experts and hard-working, dedicated staff. A well-defined marketing and branding policy allied to giving the best support to our dealers, services to customers and instilling brand confidence along with loyalty with an approach that keeps vendors tied to delivering the best to us.

When it comes to manufacturing, Mahan Industries redefines processes, reinventing and achieving better quality at reduced costs and higher efficiencies through a continuous evaluation process. We can proudly claim to have one of the best TMT manufacturing processes backed by equipment and handled by experts at each stage.

Mahan TMT Bar

Mahan TMT bar is manufactured by mahan industries. This is first thermo mechanical technology in Bihar. This is used in Mahan TMT Bar. For this, we are using temcor technology. This is only used by Tata and sale in India. We have a team of expert engineers and technocrat. They are working day night for best quality TMT BAR.

Mahan industries unit is located in Patna at didarganj area. in the Mahan industries , we are focusing on quality control, less electricity, best in quality.

Advantages

High Strength: TMT bars have excellent tensile strength, making them capable of withstanding heavy loads and providing structural stability. They have a high yield strength, which means they can resist deformation and maintain their shape even under significant stress.

Ductility: TMT bars exhibit high ductility, which allows them to undergo plastic deformation without fracturing. This property is crucial in areas prone to earthquakes, as it enables the bars to absorb and distribute the seismic forces, reducing the risk of structural failure.

Flexibility: TMT bars offer excellent flexibility, allowing for easy bending, shaping, and customization according to the specific requirements of the construction project. They can be cut and welded to suit various design needs, making them versatile and adaptable in different construction applications.

Superior Weldability: TMT bars have excellent weldability, which means they can be easily joined together using various welding techniques. This allows for efficient and reliable connections during construction, ensuring the integrity and strength of the overall structure.

Corrosion Resistance: TMT bars are designed to be corrosion-resistant. They are typically manufactured with a protective coating or with added corrosion-resistant elements such as chromium, phosphorus, or copper. This corrosion resistance ensures the longevity and durability of the bars, even in harsh environments.

Fire Resistance: TMT bars exhibit high fire resistance due to their unique manufacturing process. During production, the bars undergo rapid cooling after the hot rolling process, resulting in a tough outer layer with a tempered martensite structure. This structure enhances their ability to withstand high temperatures and provides fire resistance, ensuring the structural integrity of buildings during fire incidents.

Cost-Effective: Despite their superior properties, TMT bars are cost-effective compared to other alternatives like conventional mild steel bars. They offer a favorable balance between cost and performance, making them an economical choice for construction projects.

Earthquake Resistance: TMT bars are specifically designed to enhance the seismic resistance of structures. Their high strength, ductility, and ability to absorb and distribute seismic forces make them an ideal choice in earthquake-prone areas. TMT bars help in reducing the risk of structural damage and ensure the safety of occupants during seismic events.

Sustainable Construction: TMT bars can contribute to sustainable construction practices. Their durability and longevity reduce the need for frequent repairs and replacements, resulting in lower maintenance costs and a reduced environmental impact.

Excellent Bonding with Concrete: TMT bars have a ribbed or twisted surface, which enhances their bonding with concrete. This improved bond ensures a strong connection between the bars and the surrounding concrete, resulting in better load transfer and structural integrity.

Reduction in Construction Time: TMT bars allow for faster construction due to their easy workability and weldability. They can be easily cut, bent, and joined, which speeds up the construction process and reduces labor and time requirements.

Lighter Weight: TMT bars are lighter in weight compared to traditional mild steel bars, making them easier to handle and transport. This characteristic also reduces the overall dead load of the structure, allowing for more efficient design and cost savings.

Lower Risk of Cracks: TMT bars have a lower risk of developing cracks compared to conventional steel bars. The manufacturing process of TMT bars involves controlled cooling, which results in a fine-grained structure. This finer structure provides improved resistance against crack propagation, ensuring the durability and longevity of the structure.

Enhanced Fatigue Strength: TMT bars exhibit superior fatigue strength, which means they can withstand repeated stress cycles without failure. This property is particularly beneficial in structures subjected to dynamic or cyclic loading, such as bridges, where TMT bars can withstand the constant stress and strain without compromising the structural integrity.

Uniform and Consistent Quality: TMT bars are manufactured using advanced technology and stringent quality control measures. This ensures that the bars have uniform strength, dimensions, and mechanical properties throughout their length. The consistent quality of TMT bars provides reliability and eliminates variations in structural performance.

Eco-Friendly: TMT bars are considered environmentally friendly as they can be recycled. The recycling process of steel helps reduce the demand for raw materials and conserves energy, making TMT bars a sustainable choice for construction projects.

Compliance with Standards: TMT bars are produced according to various national and international standards, ensuring their quality, performance, and compliance with safety regulations. Using TMT bars in construction projects provides assurance that the materials meet the necessary standards for structural integrity and safety.

Applications

Buildings and High-peak Apartments Construction

Columns: TMT bars are extensively used in constructing vertical load-bearing columns. The bars provide the necessary reinforcement to withstand compressive forces and ensure the structural integrity of the building.

Beams: TMT bars are commonly used in constructing beams, which are horizontal load-bearing members that support the weight of the structure. The bars reinforce the beams and help distribute the load evenly, preventing sagging or failure.

Slabs: TMT bars are essential components in constructing slabs, such as flat roofs and floor slabs. They provide reinforcement to resist bending and cracking caused by loads and ensure the stability and longevity of the structure.

Foundations: TMT bars are crucial for building strong and stable foundations. They are used to reinforce the footing and ensure it can withstand the weight of the structure above. The bars help distribute the load and prevent settlement or structural damage.

Walls: TMT bars are sometimes incorporated into the construction of walls, especially in high-rise buildings or structures that require added strength. The bars reinforce the walls and enhance their resistance to lateral forces and structural stability.

Staircases: TMT bars are used in the construction of staircases to reinforce the steps and support the weight of people moving up and down. They provide strength and durability to ensure the safety of the staircase.

Lintels: TMT bars are utilized in lintel construction. Lintels are horizontal structural elements placed above doors, windows, and openings to bear the load from the structure above. TMT bars reinforce the lintels and prevent sagging or cracking.

Retaining Walls: TMT bars are employed in the construction of retaining walls, which are designed to retain soil and prevent erosion. The bars provide reinforcement to withstand the lateral pressure exerted by the retained soil.

Overhead Water Tanks: TMT bars are used in the construction of overhead water tanks to provide structural stability and reinforcement. The bars ensure the tank can withstand the weight of the water and remain intact over time.

Dams Construction

Spillway Structures: TMT bars are used in the construction of spillway structures in dams. Spillways are designed to safely release excess water from the reservoir during periods of high flow or flood conditions. The bars provide reinforcement to the spillway walls, slabs, and other components, ensuring their strength and durability.

Dam Crest and Abutments: TMT bars are employed in the construction of the dam crest and abutments. The bars reinforce these critical areas of the dam, which are responsible for holding back the water and transferring the loads to the foundation. TMT bars enhance the stability and structural integrity of the crest and abutments.

Foundation Reinforcement: TMT bars are used to reinforce the foundation of the dam. The bars are embedded in the concrete foundation to provide strength and stability, ensuring that the dam can withstand the water pressure and other external forces.

Spillway Gates and Operating Mechanisms: TMT bars may be utilized in the construction of spillway gates and their operating mechanisms. These components control the flow of water through the spillway. TMT bars reinforce the gates and ensure their functionality and longevity.

Intake Structures: TMT bars are employed in the construction of intake structures in dams. Intake structures are designed to control and regulate the flow of water into the dam reservoir. The bars reinforce the walls, slabs, and other components of the intake structure, ensuring their strength and durability.

Outlet Works: TMT bars are used in the construction of outlet works in dams. Outlet works are structures that control the release of water from the dam for various purposes, such as power generation or irrigation. The bars reinforce the outlet works and provide the necessary strength to withstand the hydraulic forces and pressure.

Penstocks: TMT bars may be utilized in the construction of penstocks, which are large pipes or conduits that carry water from the dam reservoir to the turbines for hydropower generation. The bars reinforce the penstocks and ensure their ability to withstand the water pressure and other operational forces.

Dam Buttresses: TMT bars are used in the construction of dam buttresses. Buttresses are external supports or reinforced concrete walls that provide additional stability and strength to the dam structure. The bars reinforce the buttresses and help distribute the loads effectively.

Building Power Plants

Turbine Hall Structures: TMT bars are used in the construction of turbine hall structures in power plants. The bars reinforce the columns, beams, and other components of the turbine hall, providing strength and stability to support the heavy machinery and equipment.

Boiler Support Structures: TMT bars are employed in the construction of boiler support structures. These structures provide the necessary support for the boiler units in power plants. The bars reinforce the support columns, beams, and platforms, ensuring their strength and stability.

Chimneys and Stacks: TMT bars are used in the construction of chimneys and stacks in power plants. These structures are designed to exhaust the combustion gases and emissions from the power plant. The bars provide reinforcement to the chimneys and stacks, ensuring their structural integrity and resistance to wind and other environmental forces.

Cooling Towers: TMT bars may be utilized in the construction of cooling towers in power plants. Cooling towers are responsible for dissipating heat from the power generation process. The bars reinforce the tower structures and ensure their strength and stability under varying thermal and environmental conditions.

Transformer Yards: TMT bars are employed in the construction of transformer yards in power plants. Transformer yards house the transformers and other electrical equipment necessary for power transmission and distribution. The bars reinforce the yard structures and ensure their stability and durability.

Cable Trenches and Ducts: TMT bars are used in the construction of cable trenches and ducts in power plants. These structures provide pathways for electrical cables and conduits. The bars reinforce the trenches and ducts, ensuring their strength and protection of the electrical infrastructure.

Control Room Structures: TMT bars may be utilized in the construction of control room structures in power plants. Control rooms house the monitoring and control equipment for the power generation process. The bars reinforce the control room buildings, ensuring their stability and protection of critical equipment.

Substation Structures: TMT bars are used in the construction of substation structures within power plants. Substations house the electrical equipment for transforming and distributing power within the plant. The bars reinforce the substation structures, ensuring their stability and reliability in power distribution.

Switchyard Structures: TMT bars may be employed in the construction of switchyard structures in power plants. Switchyards are outdoor areas where power is transferred between the power plant and the transmission grid. The bars reinforce the switchyard structures, ensuring their strength and resilience in power transfer operations.

Bridges and Flyover Construction

Bridge Decks: TMT bars are used in the construction of bridge decks, which are the roadway surfaces of bridges. The bars provide reinforcement to withstand the heavy loads, including vehicular traffic and environmental forces, such as wind and temperature variations.

Piers and Abutments: TMT bars are employed in the construction of bridge piers and abutments, which are vertical and horizontal support structures, respectively. The bars reinforce these components and help bear the weight of the bridge superstructure, ensuring their stability and strength.

Bridge Girders: TMT bars are used to reinforce bridge girders, which are the primary load-bearing members of a bridge. The bars provide tensile strength and enhance the structural integrity of the girders, enabling them to carry heavy loads across long spans.

Expansion Joints: TMT bars are incorporated into expansion joints in bridges and flyovers to accommodate the thermal expansion and contraction of the structure. The bars reinforce these joints and ensure their durability and functionality over time.

Stay Cables: In cable-stayed bridges, TMT bars are used as stay cables. These cables provide support to the bridge deck by transmitting the vertical and horizontal forces to the bridge towers or pylons. TMT bars offer high tensile strength and corrosion resistance, making them suitable for this application.

Flyover Supports: TMT bars are utilized in the construction of flyover supports, such as columns and piers. The bars reinforce these structural elements and ensure their stability and load-bearing capacity.

Reinforced Joints: TMT bars are used to reinforce the joints and connections between different bridge components, such as girders and piers. The bars enhance the structural integrity of these connections and prevent failure or deformation under heavy loads or dynamic forces.

Bearing Pads: TMT bars can be incorporated into bearing pads, which are placed between bridge components to provide flexibility and absorb vibrations caused by traffic or external forces. The bars reinforce the bearing pads and help distribute the load evenly.

Factory and Industry Establishment

Manufacturing Facilities: TMT bars are used in the construction of manufacturing facilities such as factories and industrial plants. They provide structural reinforcement for the buildings, ensuring their strength and stability in heavy-duty industrial environments.

Warehouses and Storage Facilities: TMT bars are employed in the construction of warehouses and storage facilities. These structures require strong foundations and durable frameworks to support heavy loads of goods and materials. TMT bars reinforce the walls, columns, and beams, ensuring the structural integrity of these facilities.

Petrochemical and Refinery Plants: TMT bars are used in the construction of petrochemical and refinery plants. These facilities operate in demanding environments with high temperatures, chemical exposure, and heavy equipment. TMT bars provide reinforcement to the structures, ensuring their resistance to corrosion and structural stability.

Power Generation Facilities: TMT bars are utilized in the construction of power plants, including thermal power plants, hydroelectric power plants, and renewable energy facilities. They reinforce the structures such as turbine halls, boiler support structures, cooling towers, and transformer yards, ensuring their strength and stability in the power generation process.

Mining and Extraction Industries: TMT bars are used in the construction of mining and extraction facilities, including mines, processing plants, and refineries. They provide structural reinforcement for various components, such as conveyors, storage tanks, and processing equipment, ensuring the safety and durability of these industrial facilities.

Automotive and Aerospace Manufacturing: TMT bars find application in the construction of automotive and aerospace manufacturing facilities. These facilities require robust structures to support heavy machinery, assembly lines, and storage areas. TMT bars reinforce the buildings, ensuring their stability and strength in these dynamic manufacturing environments.

Food Processing Plants: TMT bars are employed in the construction of food processing plants, including dairy processing plants, meat processing facilities, and beverage production units. They reinforce the structures, ensuring their stability and ability to withstand the hygienic requirements and heavy equipment used in the food processing industry.

Chemical Processing Plants: TMT bars are used in the construction of chemical processing plants that produce various chemicals and petrochemical products. The bars provide structural reinforcement to the facilities, ensuring their durability and resistance to chemical corrosion and exposure.

Pharmaceutical Manufacturing Facilities: TMT bars find application in the construction of pharmaceutical manufacturing facilities. These facilities require precise and controlled environments to meet stringent regulations. TMT bars reinforce the structures, ensuring their stability and ability to accommodate the specialized equipment and processes involved in pharmaceutical production.

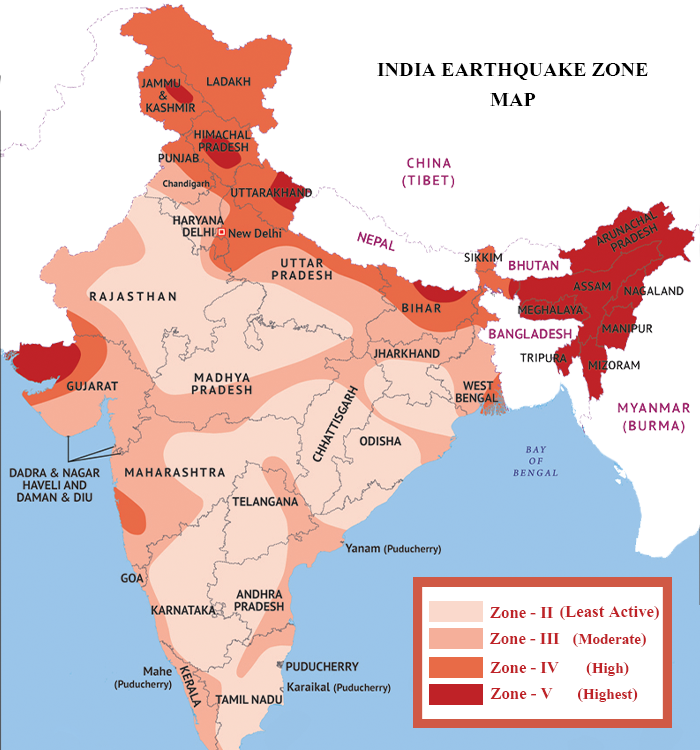

Plays Crucial Role in Seismic Zones

TMT bars are particularly valuable in seismic zones due to their enhanced strength and ductility, making them suitable for construction in areas prone to earthquakes. Here are some specific applications of TMT bars in seismic zones:

- Building Structures: TMT bars are extensively used in the construction of building structures such as columns, beams, and slabs in seismic zones. The bars provide reinforcement, enhancing the structural integrity and resistance of buildings against seismic forces. They help in absorbing and distributing the energy generated during an earthquake, reducing the risk of structural damage or collapse.

- Shear Walls: TMT bars are employed in the construction of shear walls, which are vertical structural elements designed to resist lateral loads caused by earthquakes. Shear walls provide stability and help in distributing the seismic forces throughout the structure. TMT bars reinforce the shear walls, increasing their strength and ability to withstand horizontal forces during seismic events.

- Reinforced Concrete Foundations: TMT bars are used in the construction of reinforced concrete foundations in seismic zones. Foundations play a critical role in transferring the load of the structure to the ground. TMT bars provide reinforcement to the foundation, ensuring its stability and resistance to seismic forces.

- Retrofitting and Strengthening: TMT bars are employed in retrofitting and strengthening existing structures in seismic zones. Retrofitting involves reinforcing older structures to improve their resistance to earthquakes. TMT bars are used to add additional reinforcement to the structure, enhancing its seismic performance and reducing vulnerability to seismic events.

- Bridges and Flyovers: TMT bars find extensive application in the construction of bridges and flyovers in seismic zones. These structures are subjected to significant dynamic loads during earthquakes. TMT bars provide reinforcement to the bridge piers, abutments, and decks, increasing their strength and resilience to seismic forces.

- Elevated Water Tanks: TMT bars are used in the construction of elevated water tanks in seismic zones. These tanks need to withstand the lateral forces exerted during an earthquake. TMT bars provide reinforcement to the tank walls and base, ensuring their structural stability and preventing water leakage or collapse.

- Retaining Walls: TMT bars find application in the construction of retaining walls in seismic zones. Retaining walls are designed to resist soil pressure and lateral loads. TMT bars reinforce the walls, increasing their strength and ability to withstand seismic forces and prevent soil failure.

-

Seismic Isolation Systems: TMT bars can be utilized in the construction of seismic isolation systems, which are designed to reduce the transmission of seismic vibrations to the superstructure. These systems incorporate TMT bars in the base and isolating devices, allowing the structure to move independently during an earthquake, thus minimizing damage.

Manufacturing Process